Manufacturers rarely get the luxury of a blank canvas. Production lines evolve, equipment accumulates, and before long every square metre is working overtime. That’s exactly where the Compact Palletiser excels. Instead of forcing facilities to reorganise around bulky palletising systems, it delivers industrial‑grade performance in a fraction of the footprint—without compromising throughput or flexibility.

Whether integrating into an existing line or planning a new facility, the Compact Palletiser offers a practical, space‑efficient route to automation where conventional systems simply won’t fit.

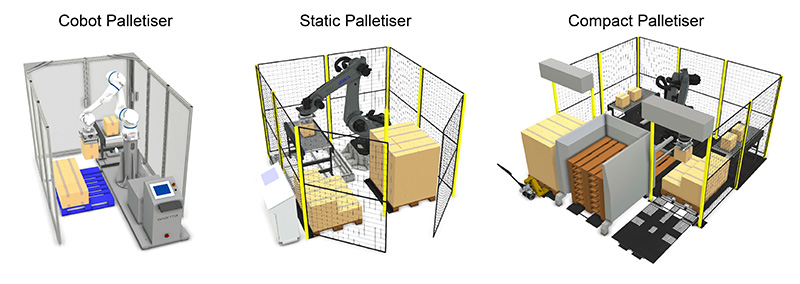

Palletising Designed for Space‑Constrained Facilities

The Compact Palletiser addresses a core manufacturing challenge: achieving automated palletising with automatic pallet feeding in tight spaces. Traditional systems rely on long conveyors and large buffer zones, limiting layout flexibility. Granta’s solution is deliberately streamlined—combining a low‑profile conveyor arrangement with a high‑performance robotic arm to create a self‑contained palletising cell that fits where others can’t.

Its compact footprint makes it ideal for small or awkward spaces. Depending on the configuration, finished pallets can be removed manually or via low‑profile conveyors, enabling high productivity without requiring extensive staging areas.

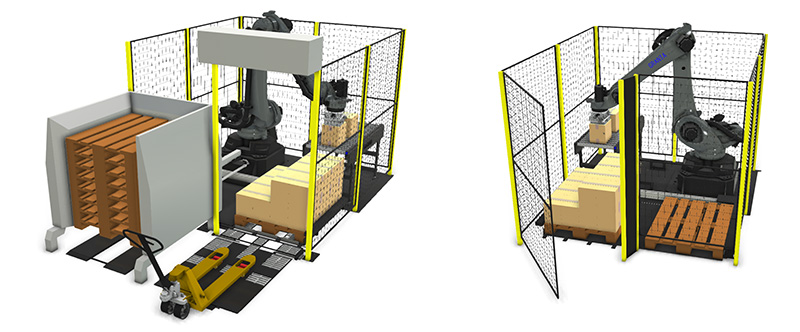

Efficient Pallet Removal for Any Workflow

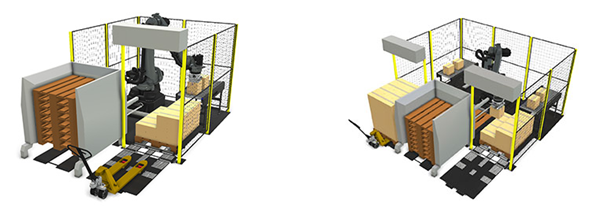

A major advantage of the Compact Palletiser is its flexibility in how finished pallets are removed. Every configuration is designed to work seamlessly with both forklift trucks and pallet trucks at floor level. This makes the system uniquely able to integrate into existing material‑handling routines where only pallet trucks or powered pallet trucks (PPTs) are safe to use. Many production areas have health and safety requirements that prevent the use of counterbalance forklifts and normal conveyor systems cannot be unloaded without this or ramps which are both regarded as dangerous. Granta Automation has developed this low level pallet movement system and is the only system in the world with this low level automated pallet movement with pallet truck take off for all pallet types. Whether the facility relies on manual pallet trucks, electric pallet movers, or full forklift operations the compact system covers all requirements.

Modular Configurations Built Around Your Production Needs

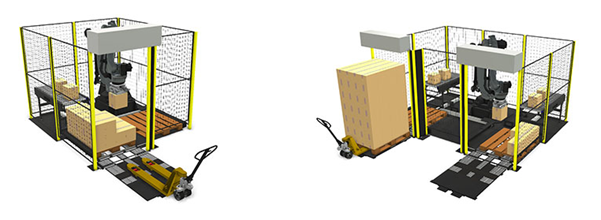

The Compact Palletiser is available in three configurations—each offered as a single or double lane cell and tailored to different throughput and automation requirements:

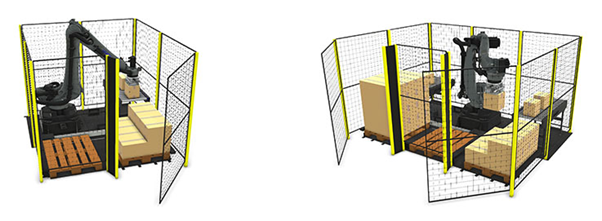

Compact Palletiser Static

The simplest and most cost‑effective option. Empty pallets are loaded manually, and full pallets are removed by forklift or pallet truck. Ideal for manufacturers seeking reliable, entry‑level automation with minimal integration complexity.

Compact Palletiser Auto

Includes low‑profile conveyors to automatically transport full pallets out of the cell while the robot continues working. Empty pallets can be placed into the cell manually without stopping the robot. This continuous‑operation design reduces downtime and boosts throughput—perfect for faster‑paced production environments.

Compact Palletiser Auto with Pallet Feeder

A fully automated solution. With automatic pallet feeding and flow‑through capability, the robot operates uninterrupted, handling multiple pallets seamlessly. Designed for high‑speed, multi‑product lines where manual intervention must be kept to a minimum.

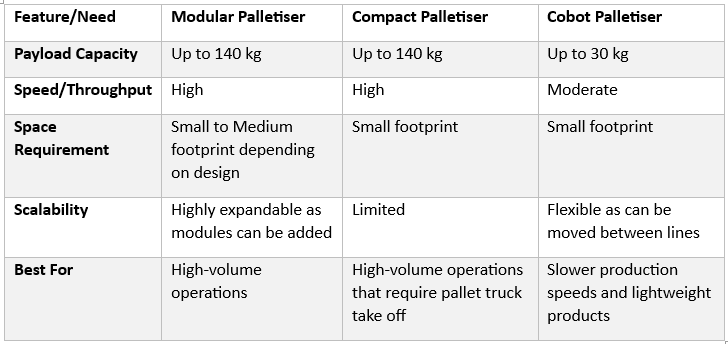

Comparison of Compact Palletiser Configurations

| Feature | Static | Auto | Auto with Pallet Feeder |

| Footprint | Smallest | Slightly larger; includes outfeed conveyors | Largest; includes pallet feeder and outfeed conveyors |

| Automation Level | Manual pallet loading/removal | Semi‑automatic: pallets fed manually and removed automatically | Fully automatic: pallets fed and removed automatically |

| Throughput | Moderate | High | Very high; continuous operation |

| Robot Operation | Stops for pallet changes | Continues while pallets are manually added and removed | Uninterrupted operation with automatic pallet feed and removal |

| Product Types | Boxes, cartons, trays, shrink‑wrapped packs, etc. | Boxes, cartons, trays, shrink‑wrapped packs, etc. | Boxes, cartons, trays, shrink‑wrapped packs, etc. |

| Ideal Applications | Entry‑level automation; limited production | Faster‑paced lines needing continuous pallet removal | High‑speed, multi‑product lines with minimal manual intervention |

| Key Benefits | Low cost, easy to install, space‑saving | Reduced downtime, higher throughput, flexible | Maximum uptime, minimal manual handling, scalable automation |

| Operator Interaction | Manual loading/removal | Manual loading/removal | Minimal; largely hands‑free apart from loading stacks of empty pallets and removing stacked pallets |

Performance and Flexibility Without Compromise

Compact doesn’t mean limited. The system is engineered for industrial‑strength performance, handling payloads up to 140 kg. A wide range of end‑of‑arm tooling—vacuum, mechanical, or bespoke—allows it to handle cartons, trays, shrink‑wrapped packs, and more.

Advanced control software ensures precise stacking, while row‑pick and multi‑pick capabilities accelerate cycle times on demanding lines.

Why the Compact Palletiser Is a Game‑Changer

In an industry where space, flexibility, and uptime are critical, the Compact Palletiser enables manufacturers to deploy advanced high speed palletising in areas previously considered too small or not safe enough. From manually fed static cells to fully automated pallet‑feeding systems, it offers scalable solutions for every production level.

By combining space‑efficient engineering with intelligent control, and low automatic pallet moving through the system Granta Automation’s Compact Palletiser proves that high‑performance automation doesn’t require a large footprint. For space‑restricted facilities, it’s more than a palletiser—it’s a strategic enabler of efficiency, safety, and operational agility.

If you’d to discuss you automated palletising requirements, feel free to contact us on 01223 499488 or helpline@granta-automation.co.uk and we will be happy to help.

Find out more…

- Driving Operational and Financial Excellence in Manufacturing: A Comprehensive Guide

- Planning for 2026: How Granta Automation Can Transform Your Operations with Palletisers and AMRs

- Which Palletiser System Is Best for Palletising Boxes?

- Common Pitfalls in Scaling Manufacturing Operations

- What is an Automated Guided Vehicle (AGV) and What are the Benefits of Investing in One?