Yes, it is possible to automate the process of stacking items from a pallet onto a machine; this process is often known as depalletising or pallet de-stacking. It is effectively the reverse operation of palletising product, and automating this process can significantly improve efficiency, speed, and accuracy in industrial processes.

Depalletising is typically performed where the items need to be unloaded from the pallet and further processed, distributed, or placed into another system or production line. There are various methods and technologies that can be used to achieve automated de-stacking. Here are a few examples:

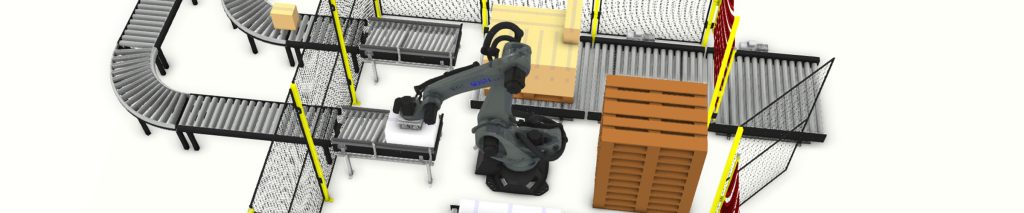

- Robotic depalletising: Robotic depalletising involves the use of a robotic arm or gantry systems to unload items from the pallet. These robots can be programmed to a pre-set stack pattern or can be programmed to identify and locate the items on the pallet using sensors, cameras, or other detection mechanisms. It will then grip and lift them, and place them onto a conveyor or other downstream equipment. Typically, a vacuum pick gripper is used for robotic depalletising and will either pick product singularly or in multiples depending on the product and speeds required. Robotic depalletising offers high speed, precision, and efficiency, making it suitable for high-volume operations or repetitive tasks.

- Layer depalletising: Layer depalletising involves removing entire layers of items from the pallet simultaneously. It often employs mechanical or robotic systems that can lift and transfer an entire layer of items onto a conveyor or other equipment. Layer depalletising is efficient and can be suitable for operations where items are uniformly stacked on the pallet. Once the product is placed on the conveyor, devices such as pushers, diverter arms, or pneumatic actuators that push or separate the items from each other, are be used to separate the product as required.

- Push-off depalletising: Push-off depalletising utilizes mechanical devices to push or slide items off the pallet. This method is commonly used for items that have a low coefficient of friction, such as cases or boxes. The mechanical device pushes the items in a controlled manner, allowing them to slide off the pallet and onto a conveyor or other equipment. Once the product is placed on the conveyor, devices such as pushers, diverter arms, or pneumatic actuators that push or separate the items from each other, are be used to separate the product as required.

These are just a few examples of automated systems that can be used for de-stacking items from a pallet into a machine. The specific choice of automation method depends on factors such as the type of items being depalletised, the desired speed and precision required, and the available budget. Implementing automated de-stacking systems often requires careful planning, integration, and customization based on the specific requirements of the operation to ensure that you get the best outcome for your requirements.

If you would like to discuss your application in more detail, please contact us on 01223 499488 or contact us at helpline@granta-automation.co.uk.

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 81

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 86