In today’s fast paced manufacturing and logistics landscape, the efficient palletising of boxes is essential for optimising space, reducing labour costs, and ensuring smooth operations. Traditional palletising methods often struggle to meet the evolving demands of today’s fast-paced industries.

Each of the Granta box palletising systems offer unique advantages, from maximising efficiency in limited spaces to enhancing safety and flexibility through human-robot collaboration, and providing adaptable, scalable solutions for dynamic production environments. Understanding the merits of these innovative palletising systems can help you choose the right technology to optimise your operations.

Cobot palletisers are increasingly becoming the go-to solution for businesses that require a blend of automation and human interaction in their palletising operations. This dual-mode capability allows the cobot to optimise both speed and payload capacity, depending on the operational requirements.

Key Features of the Granta Cobot Palletising System:

- 30kg Payload Collaborative Robot: The Granta system is equipped with a robust cobot capable of handling up to 30kg, making it suitable for palletising a wide range of box sizes and weights.

- Sturdy Industrial Design for 24/7 Use: Built for continuous operation, the Granta cobot is designed to withstand the rigors of industrial environments, ensuring reliable performance around the clock.

- Easy Programming Software: The system includes intuitive programming software, allowing operators to set up and adjust palletising tasks quickly without requiring extensive training or expertise.

- Variety of Gripper Options: The Granta cobot can be equipped with a variety of vacuum grippers to handle different types of boxes and packaging, providing flexibility for various palletising applications.

- Quick Installation: The system is designed for rapid deployment, minimising downtime and allowing businesses to start improving their palletising process quickly.

- Optional Guarding: Depending on the specific safety requirements of the operation, the Granta cobot palletiser can be used with or without guarding, offering flexibility in its implementation.

Merits of Cobot Box Palletisers:

- Safety and Collaboration: The Granta cobot is equipped with intelligent force sensing, enabling it to operate safely alongside human workers. In collaborative mode, the cobot runs at reduced speeds and can detect unexpected forces, stopping immediately if an obstruction is encountered. This feature ensures a safe working environment and reduces the risk of injury.

- Enhanced Productivity: When operating in industrial robot mode—where full safety measures are in place and no personnel are within the safe zone—the cobot can run at full speed, significantly increasing palletising efficiency. This dual-mode operation allows businesses to maximise productivity while maintaining a high standard of safety.

- Adaptability: The cobot’s ability to switch between collaborative and industrial modes makes it highly adaptable to different production environments. Whether working alongside human operators or handling tasks autonomously, the Granta system can easily adjust to meet varying operational needs.

- Ease of Use: With its user-friendly programming software and quick installation process, the Granta cobot palletiser is designed to be accessible and straightforward to use, even for operators with no experience in automation.

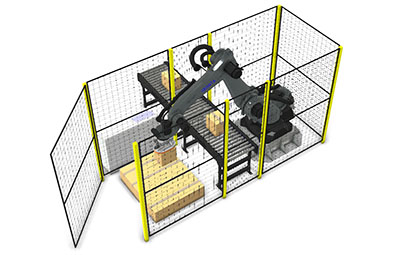

Compact palletisers are designed to deliver high-performance palletising in environments where space is at a premium. These systems are ideal for applications that require the power of an industrial robot but also need to accommodate space constraints and allow for pallet truck access. The compact palletiser system excels in such scenarios, offering a blend of efficiency, speed, and ease of use.

Key Features of the Compact Palletiser System:

- Pallet Truck Take-Off: The system is specifically designed to allow pallets to be removed using a pallet truck, making it convenient for operations where forklift access might be limited or where quick pallet removal is necessary.

- Space-Efficient Design: As the name suggests, the compact palletiser is built to occupy minimal floor space while still providing robust palletising capabilities. Its design allows for integration into production lines where every square foot counts.

- Low Profile Conveyors: The inclusion of low-profile conveyors ensures smooth and efficient movement of boxes through the palletising process without requiring excessive vertical space, further enhancing the system’s compact nature.

- 120kg Payload Robot: The system is equipped with a powerful robot capable of handling payloads up to 120kg, making it suitable for a wide range of box sizes and weights. This high payload also enables the robot to pick multiple products at a time which further enhances the speeds and cycle time.

- Variety of Gripper Options: A selection of grippers is available to suit different types of boxes and packaging materials, providing flexibility for diverse palletising applications.

- Quick Installation: The compact palletiser is designed for fast and straightforward installation, allowing businesses to quickly implement the system and start reaping its benefits without significant downtime.

Merits of the Compact Palletiser System:

- Optimised for High-Speed Lines: Despite its small footprint, the compact palletiser is capable of high-speed operation, making it an ideal solution for production lines that require quick and efficient palletising. The system can also include row gripping capabilities if needed, further enhancing its speed and efficiency.

- Automated Pallet and Slip Sheet Handling: The system can be configured to include automated pallet feeding and slip sheet placement, which helps streamline the palletising process and reduces the need for manual intervention. This automation is particularly beneficial in high-throughput environments where speed and consistency are critical.

- User-Friendly Operation: The compact palletiser features easy-to-use programming software, enabling operators to set up and modify palletising tasks with minimal effort. This user-friendly interface reduces the learning curve and ensures that the system can be operated effectively with limited training.

- Space-Saving Efficiency: The compact design of this palletiser does not compromise its capabilities. It is specifically engineered to deliver high-speed, efficient palletising in a small footprint, making it perfect for facilities with limited space.

The modular palletiser system is a highly adaptable solution, designed to meet the diverse needs of today’s industries. It offers unparalleled flexibility and ease of use, making it suitable for a wide range of palletising applications, from standard pick-and-place tasks to more complex high-speed layer forming.

Key Features of the Modular Palletiser System:

- User-Friendly Programming: The system is designed for fast and straightforward programming, eliminating the need for specialist skills. Operators can quickly set up palletising tasks, making it an accessible option for facilities of all sizes.

- Automatic Stack Generation: With automatic stack generation available at the touch of a button, the system can handle an infinite variety of products, pallets, and stack configurations. This feature is particularly valuable for businesses that deal with a wide range of product sizes and types.

- 120kg Payload Robot: The system is equipped with a powerful robot capable of handling payloads up to 120kg, making it suitable for a wide range of box sizes and weights. This high payload also enables the robot to pick multiple products at a time which further enhances the speeds and cycle time.

- Versatile Applications: The modular palletiser is capable of handling everything from standard pick-and-place palletising of bags or boxes to high-speed layer forming. It’s also equipped to handle automated container unloading and palletising, expanding its utility across various tasks.

- Fully Automated Programming: For operations that frequently change the sizes and types of products being palletised, the system offers a fully automated programming option. This feature allows for the automatic setup of pallet stack patterns and robot programming, significantly reducing setup time and enhancing operational efficiency.

- Reconfigurable Design: The modular nature of the system means it can be easily and quickly reconfigured to meet changing production requirements. This adaptability ensures that the system remains relevant and effective as business needs evolve.

Merits of the Modular Palletiser System:

- Flexibility and Adaptability: The modular design allows businesses to easily reconfigure the system as their production needs change. The system can be quickly adapted without major disruptions to scale with and adapt to your company needs in the future.

- Quick Installation and Short Lead Times: Thanks to its modular construction, the palletiser can be delivered and installed with minimal lead time. This rapid deployment helps businesses start improving their palletising processes sooner, reducing downtime and increasing efficiency.

- Efficiency Across Multiple Applications: Whether handling standard boxes, bags, or more complex palletising configurations, the system’s versatility ensures it can meet a wide range of needs. This makes it a valuable investment for businesses looking to streamline their operations across different products and tasks. Multiple lines can be palletised by one system.

These advanced palletising systems can all be tailored to meet our specific needs—whether it’s maximising space with a compact palletiser, improving flexibility and safety with a cobot system, or achieving adaptability and efficiency with a modular palletiser. As the industry continues to evolve, the integration of these innovative technologies will be key to maintaining competitive advantage and operational excellence.

If you would like to know more about the Granta Compact Palletising systems, then please do get in touch on 01223 499488 or contact us at helpline@granta-automation.co.uk. We will be very happy to help.

Find out more…

- What Palletiser Is Best For The Pet Food Industry?

- The Compact Palletiser: A Space-Saving Solution for Efficient Palletising

- Strategic Cost Management for Manufacturing Managers

- How to Reduce Labour Costs in Palletising

- Asset Management in Manufacturing: Lifecycle Management and Maintenance Planning