Almost any type of product can be automatically depalletised, and the best method will vary depending on the type of product that is being depalletised and the speeds required. Depalletising of boxes or bags will often be done by a robot picking and placing the items one at a time, but for high-speed applications, such as depalletising bottles onto a production line, the product will usually be picked and placed as a complete layer to meet the speeds required.

There are many different reasons why a pallet may need to be depalletised, and some of the most common reasons are listed below:

- Cross stacking product from Euro pallets to UK standard pallets to fit the UK distribution network and pallet storage system.

- Depalletising items such as empty bottles or containers onto a production line ready for filling.

- Depalletising boxes or bags off a pallet onto a conveyor ready for loading into a container for shipping.

- Depalletising and repalletising of boxes or bags to get the correct quantity or stack pattern onto a pallet.

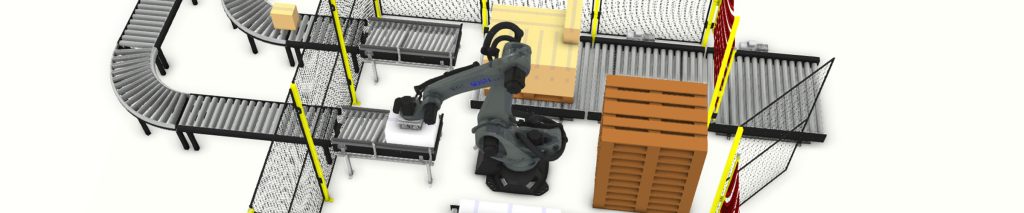

Cross stacking of bags or boxes from one pallet to another will typically be done by a robotic depalletising system and the system will usually be designed to suit your specific application and speeds. The robotic arm will pick and place one item at a time and compensator tools may be used by the robot to allow for product variations. An angled alignment frame or conveyor system may also be needed to enable the product to be accurately re-positioned onto the new pallet.

Where product is being depalletised onto a production line or onto a conveyor for loading a container, the speeds required will determine the pick and place method. For slower speed applications items will be picked and placed individually, whereas for high-speed applications a complete layer, or row can be picked and placed onto the production line. Once the product is on the conveyor, it will then be orientated and separated as required by the production process.

Typically, a depalletising system will be built to suit your exact requirements, and can be designed to include pallet wrapping and labelling if needed.

Some of the key benefits to automatically depalletising product include:

- Improved efficiency: An automated depalletising system is more efficient than manually depalletising as it will not need to stop for breaks, holidays, etc., enabling you to run your depalletising process 24/7 if required.

- Improved safety: An automated system will remove the need for manual handing of product, and therefore reduce the risk of repetitive strain injuries occurring.

- Flexibility: Some automated depalletising systems have software that can be reprogrammed by your staff which gives you flexibility and enables you to use the system to depalletise a wide variety of products on the one system.

If you would like to discuss your depalletising application, feel free to contact us on 01223 499488 or helpline@granta-automation.co.uk.

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 81

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 86