In today’s competitive manufacturing and logistics landscape, efficiency and automation are becoming indispensable for businesses of all sizes. For small businesses, however, the challenge often lies in finding cost-effective automation solutions that don’t overwhelm their limited resources. One area where affordable automation can have a transformative impact is in palletising—the process of stacking and organizing products onto pallets for transportation and storage.

While large-scale manufacturers may have the budget and space for high-end, complex palletising systems, smaller businesses need solutions that are both cost-effective and practical. The good news is that advancements in automation technology have made palletising solutions accessible and adaptable to smaller operations, helping these businesses enhance efficiency, reduce labour costs, and maintain consistent product handling—all without breaking the bank.

Why Palletising Automation Matters for Small Businesses

For small businesses, manual palletising can be a costly and time-consuming task. As businesses scale up, handling larger volumes of products manually leads to inefficiencies, bottlenecks, and increased labour costs. Furthermore, the physical demands of manual palletising—lifting, bending, and stacking—pose a significant risk of injury to employees, which could lead to absenteeism, higher insurance premiums, and reduced productivity.

Automated palletising provides a solution to these issues, helping small businesses streamline their operations, improve productivity, and enhance workplace safety. The right palletising system can drastically reduce the time spent on manual tasks, while maintaining the accuracy and consistency needed for reliable logistics.

However, smaller businesses often have limited budgets and floor space, so finding a palletising system that balances performance with cost-effectiveness is crucial. This is where specialised palletisers designed for smaller operations come into play. These systems offer the same efficiency and reliability as their larger counterparts, but in a more affordable and space-saving format.

Key Considerations for Small Business Palletisers

When evaluating affordable palletisers, small businesses should focus on several important factors to ensure they select the right system for their needs:

- Compact Design: Small businesses typically have restricted floor space in their facilities. Palletisers designed with a compact footprint can fit easily into these spaces, offering high performance without requiring extensive restructuring of the production area.

- Ease of Integration: Many small businesses operate lean, which means they can’t afford long downtime when installing new equipment. Palletisers that are easy to integrate into existing workflows and production lines ensure minimal disruption and quick start-up times.

- Flexibility: Small businesses often handle a wide variety of product types, packaging shapes, and sizes. Palletising systems that offer customisable configurations and can adapt to different product requirements provide the flexibility needed to handle varied product lines efficiently.

- Scalability: As a small business grows, its production and palletising needs will also evolve. Choosing a scalable palletiser that can grow alongside the business is a smart long-term investment. Systems that allow for future upgrades or additional capabilities help ensure that the initial investment continues to deliver value as the business expands.

- Low Maintenance and Operational Costs: Affordable palletising solutions are not just about the initial purchase price—they should also offer low ongoing costs. This includes minimal maintenance requirements, and reliable long-term operation.

- User-Friendly Operation: For small businesses without dedicated automation specialists, palletising systems need to be user-friendly and require minimal training. Intuitive interfaces and easy-to-use controls reduce the learning curve and ensure that employees can operate the system effectively without needing extensive technical knowledge.

Common Palletising Solutions for Small Businesses

Several types of palletisers stand out as particularly well-suited for small businesses, offering a balance of affordability, flexibility, and performance. These systems provide a range of automation options depending on the specific needs and constraints of the business.

1. Cobot Palletiser

Collaborative robots, or cobots, are becoming an increasingly popular choice for small businesses. Designed to work alongside human operators, cobot palletisers offer a high degree of flexibility and can be easily integrated into existing workflows without the need for large safety barriers or complex reprogramming.

Cobots are ideal for small businesses because of their:

- Ease of Use: Cobots can be quickly programmed and reprogrammed to handle different tasks, making them versatile and adaptable to various production environments.

- Space Efficiency: Cobots take up less space compared to traditional industrial robots, making them an excellent choice for businesses with limited floor space.

- Safety Features: Cobots are designed to operate safely around human workers, which allows small businesses to automate palletising tasks without needing extensive safety infrastructure.

These palletisers are a cost-effective solution for businesses looking for flexibility and reliability without the large capital investment of full-sized industrial robots.

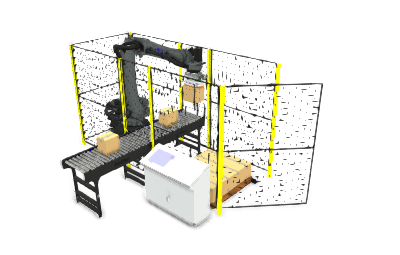

2. Compact Palletiser

As the name suggests, compact palletisers are designed with space-saving functionality in mind. These palletisers are perfect for small businesses that have limited floor space but still require the efficiency and speed of automated palletising and pallets can be loaded an removed from the system using a pallet truck rather than a fork lift.

Key features of compact palletisers include:

- Small Footprint: Compact palletisers are designed to fit into tight spaces, making them suitable for businesses with constrained production areas.

- Affordability: Compared to larger, industrial-scale palletisers, compact systems are more affordable, making them accessible to businesses on tighter budgets.

- Efficiency: Despite their size, compact palletisers offer impressive throughput, allowing businesses to increase productivity without sacrificing valuable space. Pallet can be loaded and unloaded from the system using a pallet truck, which remove the need for a forklift.

Compact palletisers are ideal for small operations that need to maximise productivity but lack the physical space for more extensive automation systems and don’t the space for a powered forklift.

3. Modular Palletiser

Modular palletisers provide businesses with the ability to scale and customize their palletising solutions as their needs evolve. These systems are built with a modular design, allowing for additional features or components to be added over time, making them a smart investment for businesses with growth potential.

The benefits of modular palletisers include:

- Scalability: As a business grows, the palletising system can be expanded by adding new modules or enhancing its capabilities. This means the system can grow alongside the business without requiring a full replacement.

- Customisability: Modular palletisers are highly customisable, allowing businesses to configure the system according to their specific production needs and product requirements.

- Cost-Efficiency: By starting with a basic setup and adding modules as needed, businesses can spread out the cost of automation while still benefiting from increased efficiency in the short term.

Modular palletisers are perfect for small businesses that anticipate future growth but need an affordable and flexible solution to start.

How Affordable Palletising Solutions Benefit Small Businesses

Investing in an affordable palletising solution can provide small businesses with a range of benefits, beyond just reducing labor costs. These include:

- Increased Efficiency: Automated palletising systems work faster and more consistently than manual labour, enabling businesses to increase their throughput and productivity.

- Improved Accuracy: Automated palletisers minimise human error, ensuring that products are stacked uniformly and correctly, reducing the risk of damage during transport and storage.

- Enhanced Worker Safety: By reducing the need for manual lifting and repetitive movements, automated palletising systems help prevent workplace injuries, contributing to a safer and more productive work environment.

- Cost Savings: Although automation involves an initial investment, it can save money in the long run by reducing labour costs, minimising product damage, and lowering the risk of workplace injuries.

Conclusion

Affordable palletising solutions are within reach for small businesses looking to automate and streamline their operations. Whether it’s a compact system designed for limited spaces, a cobot that offers flexibility and safety, or a modular palletiser that can grow with the business, there are plenty of cost-effective options available. By carefully considering your production needs, budget, and future growth, small businesses can select a palletising system that not only fits the current requirements but also helps you to scale efficiently as you grow.

With the right palletising solution in place, you can improve productivity, reduce operational costs, and stay competitive in an increasingly automated world.

If you would like to know more about the Granta palletising systems, then please do get in touch on 01223 499488 or contact us at helpline@granta-automation.co.uk. We will be very happy to help.