Automated cross-palletising is an essential automation solution in logistics and manufacturing, where products are often moved across various pallet formats to meet the diverse demands of global supply chains. Pallet sizes differ based on regional and logistical needs. For instance, while Europe predominantly uses Euro pallets, the UK and Australia favour CHEP pallets, which are larger. The challenge arises when products transported on one type of pallet need to be transferred onto another for local storage or distribution.

Automating this task streamlines the handling of goods, improves safety, and significantly boosts operational efficiency, particularly in industries where different regional pallet standards complicate logistics. Traditional manual methods of repalletising can be time-consuming, labour intensive, and error-prone, particularly when dealing with large volumes or heavy loads.

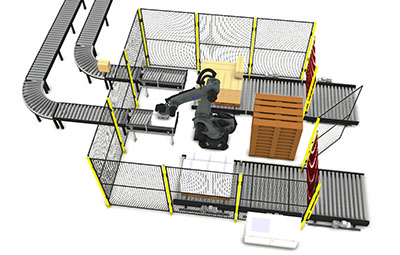

How Automated Cross-Palletising Systems Work

Most, if not all of the Granta palletising systems and layouts can be used in reverse to de-palletise or cross stack products. The robotic grippers can pick individual or multiple items from a pallet or conveyor and either place them onto another pallet or feed them into a production line in a new configuration. When incoming stacks are misaligned or unstable due to movement during transport, then an intervening process can be added to the system to align the boxes and ensure the new stack is neat and square.

Key Advantages of Automated Cross-Palletising

- Increased Productivity and Throughput: Automated systems can handle repetitive tasks far more quickly and efficiently than human workers. By eliminating manual handling, businesses can experience up to a 40% increase in productivity, as the robots maintain consistent performance without the need for breaks or shift changes.

- Cost Savings and Rapid Payback: With the reduction in manual labour, businesses can lower their operational costs. Many companies see a return on their investment in less than a year due to savings on labour, increased production speeds, and reduced error rates.

- Enhanced Safety: Manual pallet handling involves significant risks of injury, particularly when dealing with heavy or awkward loads. Automated systems eliminate these risks, as the robots perform the heavy lifting, reducing the chance of workplace accidents and improving overall safety.

- Scalability and Flexibility: These systems are designed to be adaptable. Whether handling different product sizes or adjusting to changes in pallet types, automated cross-palletising systems can be easily reconfigured to meet evolving operational needs. This scalability ensures that businesses can continue to grow without needing frequent overhauls of their systems.

- Improved Accuracy and Stack Stability: Automated systems are highly precise, ensuring that products are aligned and stacked correctly on pallets. This reduces the likelihood of load shifts or damage during transit, improving the overall integrity of shipments.

Industry Applications

Automated cross-palletising is particularly useful in industries that frequently deal with large-scale distribution, such as retail, food and beverage, pharmaceuticals, and manufacturing. For example, companies shipping products across Europe to the UK may need to move goods from Euro pallets to UK pallets upon arrival. In sectors such as food production, where speed and accuracy are critical to maintaining product freshness, automated systems play a pivotal role in ensuring swift, seamless pallet transfers.

By automating the transfer of products between different pallet types, businesses can significantly improve their operational efficiency, reduce costs, and ensure safety. With flexible programming, advanced robotics, and integration with other automated systems, these solutions provide a robust, scalable option for companies aiming to stay competitive in a rapidly evolving industrial landscape.

For more information about the Granta cross-palletising solution, visit https://www.granta-automation.co.uk/types-of-automation/depalletising-and-cross-stacking or contact us on 01223 499488 or helpline@granta-automation.co.uk. We will be very happy to help.

Find out more…

- Financial Management Strategies for CAPEX Managers in Manufacturing

- ROI Analysis: Is Investing in a Palletiser Worth It?

- Manual Palletising Efficiency Problems and How to Overcome Them

- Strategic Risk Management for CapEx Managers in Manufacturing

- Box Palletising: Cobot, Compact, and Modular Robotic Palletiser Systems