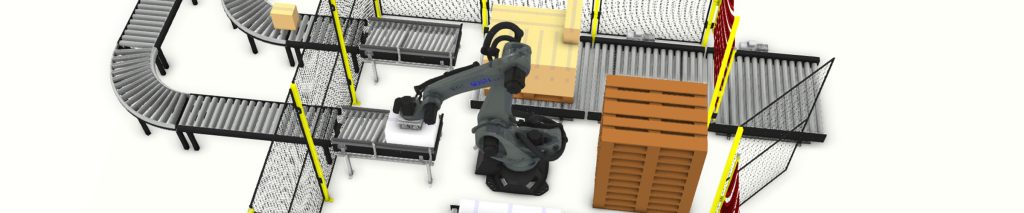

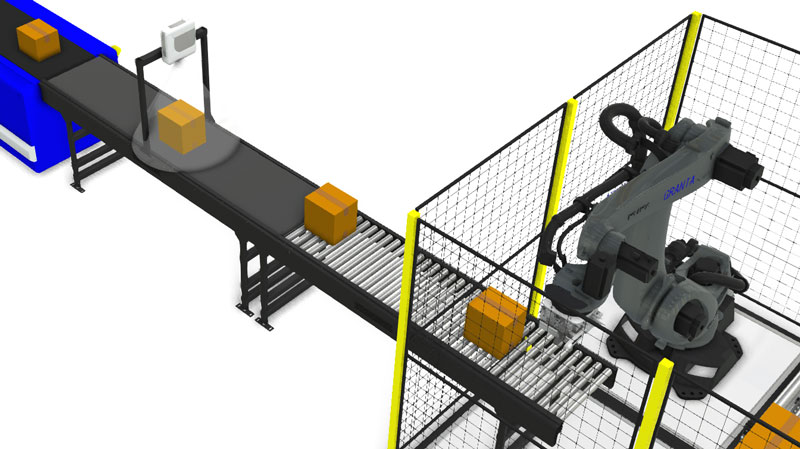

Vacuum grippers are a type of end effector that uses suction to lift and manipulate objects. They are widely used for robotic palletising, which is the process of stacking and arranging products on pallets for transportation or storage. Vacuum grippers have many advantages over other types of grippers, such as:

- They can handle a variety of objects, such as boxes, display boxes, cartons and some types of packed products and bags.

- They can lift objects from above, without needing to grip them from the sides or below.

- They can distribute the payload evenly across the object’s surface, avoiding deformation or damage.

- They can be customized to fit different sizes and shapes of objects, by adjusting the number and position of suction cups or valves.

- They can save energy and reduce noise, by using self-closing valves that only activate when needed.

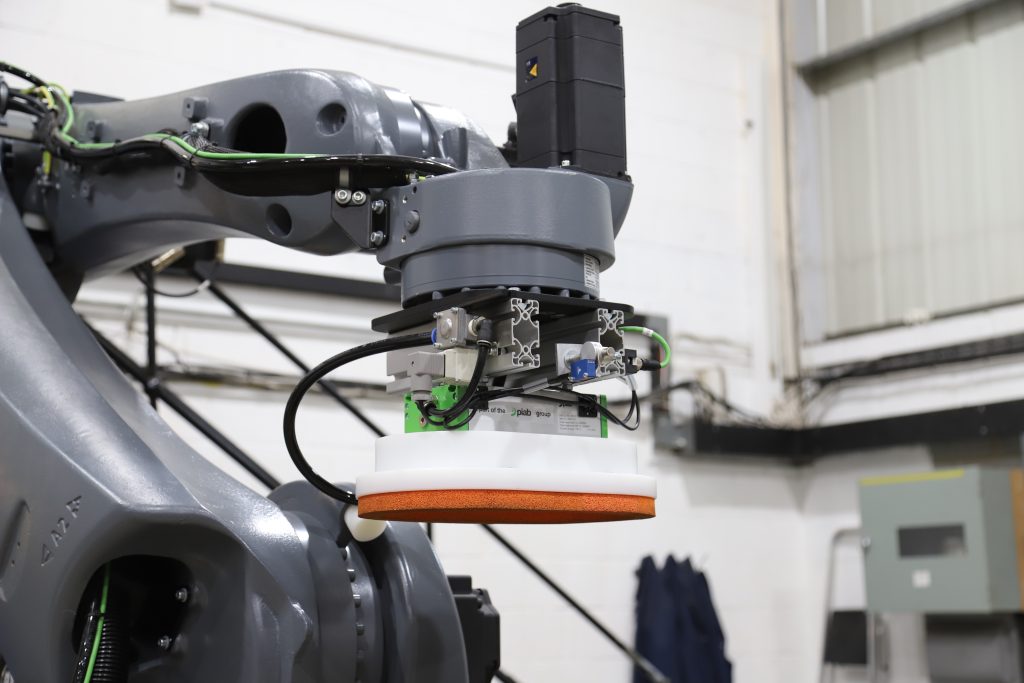

A vacuum gripper works by using suction to lift and place objects onto a pallet. It consists of a electrical vacuum pump or a venturi vacuum pump connected to a vacuum head with suction cups or a foam pad. The vacuum gripper’s design and construction can vary depending on the application requirements. Some grippers have multiple suction cups arranged in an array for increased gripping capacity and flexibility, whereas other vacuum grippers have a foam pad. The vacuum pump creates a negative pressure inside the hose and the head, which causes the suction cups or foam pad to stick to the surface of the object. The robot arm then moves the object to the desired location on the pallet and releases the suction by turning off the pump or opening a valve.

Vacuum grippers are particularly useful in situations where traditional mechanical grippers may not be suitable, such as when handling delicate or irregularly shaped objects. They are commonly used in industries such as manufacturing, warehousing, and logistics.

Some examples of the different types of vacuum gripper are shown below.

Vacuum Layer Gripper

Row Vacuum Cup Gripper

Row Vacuum Gripper

Vacuum Bag Gripper

Vacuum Bag Gripper

Vacuum Box Gripper

Vacuum Box Gripper

It’s worth noting that while vacuum grippers are efficient for many applications, they do have limitations. They rely on a certain amount of airtight seal, so they may not work effectively on some very porous or rough surfaces. Additionally, objects with irregular or curved surfaces may require specialized gripper designs or multiple suction cups to ensure a reliable grip.

Vacuum grippers are one of the best options for robotic palletising, as they offer versatility, speed, and reliability. They can improve the productivity and quality of the palletising process, while reducing the workload and risk of injury for human workers.

If you would like to discuss your application in more detail, please contact us on 01223 499488 or contact us at helpline@granta-automation.co.uk.