Investing in a palletiser is a significant step towards automation and efficiency in your production process. The right palletiser not only improves operational productivity but also provides long-term cost savings and scalability for growing businesses. However, selecting the most suitable option requires a clear understanding of your specific requirements and a structured decision-making approach.

1. Define Your Requirements Thoroughly

A comprehensive URS is a critical starting point for choosing the ideal palletiser. This document ensures your equipment aligns with operational goals and production needs. Key elements to include in your URS include:

- Production Volume and Speed: Outline your current and future production rates to determine the palletiser’s throughput capacity.

- Product Specifications: Record the dimensions, weight, and type of products (e.g., boxed goods, bagged items) you’ll be palletising. Does the product size you need to palletise change frequently? Do you need to be able to reprogram the palletiser?

- Pallet Configuration: Define stacking patterns, number of pallets required per shift, and compatibility with existing systems like conveyors. Do your stack patterns change? Do you need to be able to set up the palletiser with different stack patterns?

- Facility Constraints: Note space limitations and power supply requirements, ensuring the machine fits seamlessly into your workflow.

A detailed URS not only simplifies your search for a suitable palletiser but also provides potential suppliers with the necessary information to tailor solutions to your needs. A downloadable palletiser URS template is available here https://www.granta-automation.co.uk/palletiser-urs-template

2. Match Palletiser Types to Your Business Needs

Different types of palletisers cater to various products and production speed requirements. Selecting the right one ensures efficient operation.

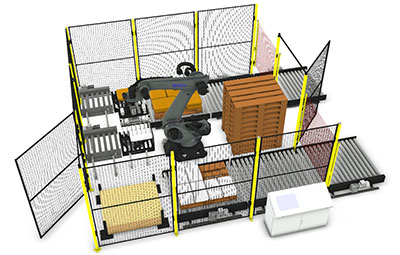

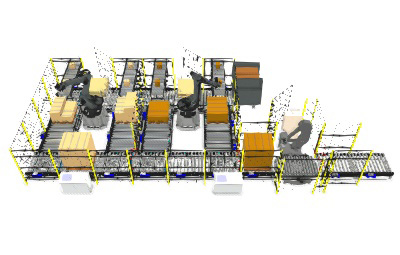

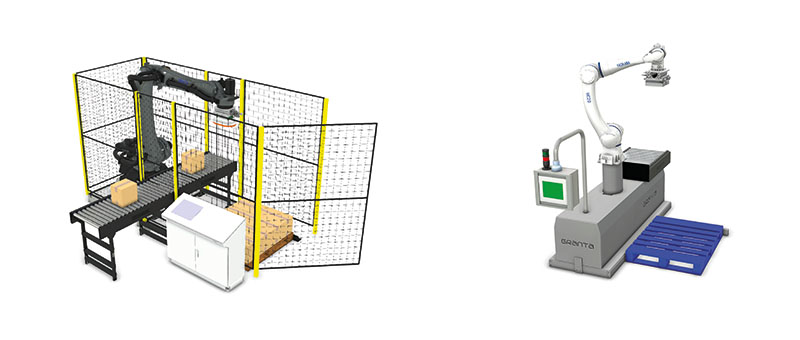

Modular Robotic Palletising System:

This palletising system is designed to handle any palletising needs with speed, efficiency, and reliability. It excels in high-speed, high-volume operations and can manage a wide variety of product types, sizes, weights, and pallet configurations, ensuring seamless integration into diverse production environments.

The system’s modular design allows for easy reconfiguration and scalability, reducing downtime and costs. Key features include:

- Exceptional versatility: Suitable for applications such as pick-and-place operations for bags, boxes, trays, and shelf-ready boxes, as well as row-picking or layer-forming for faster throughput.

- High payload capacity: With a 140kg payload, the robust robot effortlessly handles both lightweight boxes and heavier goods.

- Multi-line handling: Capable of palletising products from multiple production lines simultaneously, streamlining workflows and boosting operational efficiency.

Whether your needs involve high throughput or flexible adaptability, this system delivers reliable performance to enhance your production setup.

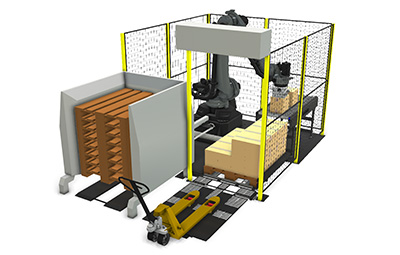

Compact Palletiser:

The Compact Palletiser is a space-saving solution tailored for high-speed palletising, ideal for facilities with limited floor space. Its design ensures high performance and is suitable for pallet truck take-off operations.

Key features of the system include:

- Autofeed pallet system: Enables uninterrupted operation by automatically feeding pallets, eliminating the need for the system to stop during pallet removal or replacement.

- Low-profile conveyors: Support pallet truck take-off, removing the need for additional equipment or larger spaces.

- Compact design: Packs essential functions into a small footprint, maintaining high performance while saving valuable floor space.

- Robust 140kg payload robot: Efficiently handles a variety of goods, from lightweight boxes to heavier items, ensuring versatility and reliability.

This system is designed to optimise workflows, enhance reliability, and deliver high speed performance in space-constrained environments.

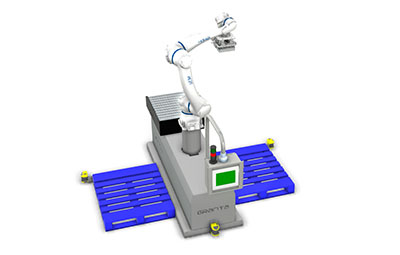

Cobot Palletiser:

The Cobot Palletiser (Collaborative Robot Palletiser) is designed to work safely alongside human operators, making it perfect for palletising lightweight products. Its dual-mode functionality allows seamless switching between collaborative and industrial robot modes, balancing safety and efficiency.

Key features include:

- Robust industrial-grade design: Ensures reliable performance in demanding environments with a 30kg payload capacity.

- Advanced safety features: Intelligent force-sensing technology detects unexpected interactions, automatically pausing operations to prevent accidents.

- Versatile gripper options: Supports various product shapes, sizes, and materials, meeting diverse palletising needs.

- Flexible safety configurations: Customisable guarding options, including setups with or without safety guards and area scanners, allow adaptation to specific facility layouts.

The Cobot Palletiser combines safety, versatility, and performance, offering a flexible and efficient solution for lightweight palletising tasks.

3. Assess Financial and Operational Benefits

The decision to invest in a palletiser should be backed by a detailed cost-benefit analysis. Consider the following:

- Labour Cost Savings: Automation reduces reliance on manual labour, minimising costs associated with wages, training, and health risks.

- Efficiency Gains: Automated systems, particularly those equipped with intuitive programming software, can significantly improve production speed and consistency. Granta Automation’s systems all come with easy-to-use programming interfaces for quick adjustments.

- Reduced Waste: Consistent palletising minimises product damage, improving customer satisfaction and reducing costs associated with returns.

- Scalability: Modular palletisers can grow with your business, eliminating the need for frequent replacements or upgrades

These calculators will help you to calculate the savings and benefits you are likely to make:

- Palletiser Savings Estimator https://www.granta-automation.co.uk/palletiser-savings-estimator

- Payback Calculator with Finance Lease Options – https://www.granta-automation.co.uk/automation-project-payback-calculator

- Intangible Benefits Calculator – https://www.granta-automation.co.uk/news/how-to-define-the-value-of-intangible-benefits/

4. Consider Practical Factors

When evaluating options, it’s essential not to overlook these considerations:

- Ease of Integration: Ensure the palletiser can be seamlessly incorporated into your existing setup. Granta’s modular systems, for instance, are known for quick installation and compatibility with various layouts.

- Operator Training: Look for user-friendly systems that don’t require specialised skills, enabling smooth operation by existing staff.

- Maintenance and Support: Assess the availability of after-sales support and maintenance plans. Robust service contracts can reduce downtime and ensure consistent performance.

5. Collaborate with Industry Experts

Choosing the right palletiser is not a decision you need to make alone. Manufacturers will be able to give you invaluable support, from site visits to tailored recommendations. Their experts can evaluate your production process, identify inefficiencies, and recommend the most suitable system based on your requirements.

Our downloadable URS template provides a structured approach to documenting your needs and making an informed decision. https://www.granta-automation.co.uk/news/downloadable-palletiser-urs-template/

Or contact us today on 01223 499488 or helpline@granta-automation.co.uk to discuss your requirements and discover how we can help you optimise your palletising processes.

Find out more…

- Ways To Speed Up The Palletising Process In Production

- How To Automate Cross Palletising and Depalletising from UK to Euro Pallets

- How Cycle Time Reduction Improves Operational Efficiency

- Autonomous Mobile Robot (AMR) Pallet Stations, Charging Stations, and Conveyor Stations

- Mastering Budget Planning: Advanced Methods for Planning and Allocating Capital Budgets in Manufacturing