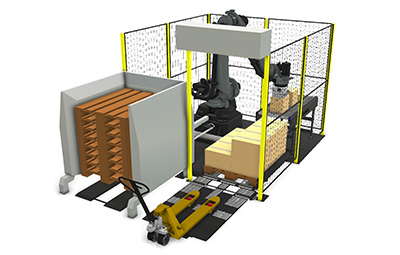

In the fast-paced world of food and beverage production, efficiency is paramount. As companies strive to meet increasing demand while maintaining quality and safety standards, the need for advanced, space-efficient palletising solutions has never been greater. Enter the Compact Palletiser—an innovative system designed to meet the demands of high-speed production lines while accommodating spatial constraints and the need for pallet truck take-off.

Key Features of the Compact Palletiser

The Compact Palletiser is a meticulously engineered solution that brings a host of powerful features to your production line:

- Pallet Truck Take-Off: One of the defining features of the Compact Palletiser is its ability to seamlessly integrate with pallet trucks, allowing for the smooth and efficient removal of full pallets. This design not only reduces the need for complex handling equipment but also ensures that your production line keeps moving without unnecessary interruptions.

- Space-Efficient Design: In many production environments, space is a critical concern. The Compact Palletiser’s design addresses this by offering a minimal footprint, allowing you to fit the system into tight spaces without sacrificing functionality or performance. This compactness is particularly beneficial for facilities looking to expand operations without a costly overhaul of their existing floor plan.

- Low Profile Conveyors: The inclusion of low profile conveyors is a game changer, as it facilitates the easy movement of products and pallets through the system. These conveyors are designed so that they can be loaded and unloaded using either a fork lift truck or a pallet truck.

- User-Friendly Programming: The system’s programming software is designed with ease of use in mind. Even operators with minimal technical experience can quickly learn to program and operate the Compact Palletiser, reducing the need for extensive training and minimising operator error. This intuitive interface also allows for quick adjustments, ensuring that you can adapt to changing production needs with minimal downtime.

- 120kg Payload Robot: At the heart of the Compact Palletiser is a powerful industrial robot capable of handling a wide range of products, from lightweight packages to heavier, bulkier items. This versatility ensures that the system can be tailored to suit the specific demands of your production line, whether you’re palletising fragile goods or heavy cases.

- Variety of Gripper Options: The ability to customise the system with different gripper configurations means that the Compact Palletiser can handle an array of product shapes and sizes. This flexibility is crucial in the food and beverage industry, where packaging types can vary widely depending on the product.

- Quick Installation: Speed is of the essence when upgrading production lines, and the Compact Palletiser is designed for rapid installation. This feature means you can minimise production downtime during setup, allowing your operations to return to full capacity swiftly.

- Adaptable for High-Speed Production Lines: One of the most significant benefits of the Compact Palletiser is its versatility. It’s not just a one-size-fits-all solution but a system that can be adapted to meet the specific demands of high-speed production lines in the food and beverage industry. Whether you require features like row gripping for delicate handling, slip sheet placement, or automated pallet feeding, the Compact Palletiser can be configured to meet these needs. This adaptability ensures that your investment in palletising technology can grow and evolve alongside your business, keeping pace with changes in production volume and packaging types.

Configurations of the Compact Palletiser System

The Compact Palletiser system is available in three distinct configurations, each tailored to different levels of automation and operational complexity:

- Compact Palletiser Static

- Overview: The Static model is the entry-level option within the Compact Palletiser range. It allows for the loading of a single new pallet while the robot continues its operation. Full pallets are removed manually through a gate, making it ideal for slower speed operations that demand efficiency and reliability.

- Operation: Available in both single and double lane configurations, the system pauses when full pallets are removed, ensuring a controlled and safe operation. Full pallets can be taken off using either a pallet truck or forklift, depending on your facility’s equipment.

- Compact Palletiser Auto

- Overview: The Auto model enhances the efficiency of the palletising process by incorporating low profile conveyors that transport finished pallets out of the cell, allowing the robot to continue its work uninterrupted. This configuration is perfect for operations that require continuous palletising without manual stops, thereby increasing overall throughput.

- Operation: This system is available in single or double lane configurations, offering flexibility to match your production line’s needs. The seamless integration with pallet trucks or forklifts for pallet removal ensures that the production flow is maintained at all times.

- Compact Palletiser Auto with Pallet Feeder

- Overview: The most advanced option in the Compact Palletiser range, this system is designed for fully automated operation. It features an automatic pallet feeder that ensures a constant supply of empty pallets, enabling the robot to operate continuously without the need for manual intervention. This model is ideal for high-capacity production lines where uptime is critical.

- Operation: This configuration supports both single and double lane systems, with a low-profile input on the pallet feeder for easy loading of empty pallets using pallet trucks or forklifts. Finished pallets are automatically transported out of the cell, creating a smooth and efficient workflow that minimises downtime and maximises productivity.

Enhancing Your Palletising Process with the Compact Palletiser

The Compact Palletiser is more than just a space-saving solution; it’s a versatile, efficient, and scalable system designed to meet the evolving needs of the food and beverage industry. Whether you’re looking to streamline operations, increase output, or simply make better use of your available space, the Compact Palletiser offers a range of configurations and features that can be tailored to your specific needs.

Investing in the Compact Palletiser means investing in a future-proof solution that enhances your production capabilities while providing the flexibility to grow and adapt as your business evolves. With its combination of robust design, user-friendly operation, and advanced automation options, the Compact Palletiser is poised to become an indispensable asset in your production line, helping you achieve greater efficiency and success in a competitive market.

If you would like to know more about the Granta Compact Palletising systems, then please do get in touch on 01223 499488 or contact us at helpline@granta-automation.co.uk. We will be very happy to help.