A palletiser is a piece of industrial equipment used to automate the stacking of products or materials onto pallets. To ensure the safety of personnel working around a palletiser, various safety mechanisms and systems are typically in place to prevent the machine from starting or operating when someone is in the cell or within its hazardous area. Here are some common safety features that can prevent a palletiser from starting when someone is in the cell:

- Safety Interlock Switches: Safety interlock switches are devices that are strategically placed at access points to the palletiser cell, such as doors or gates. When these access points are opened, the safety interlock switch is triggered, and it sends a signal to the control system of the palletiser to prevent it from starting or continuing operation.

- Light Curtains: Light curtains are sensors that create an invisible barrier of light beams across the access points to the palletiser cell. If someone breaks the light curtain by entering the cell, the control system will detect this interruption and prevent the palletiser from starting or immediately halt its operation.

- Safety Area Laser Scanners: Safety area laser scanners, can be installed within the cell to detect the presence of people or objects. If a person enters the cell, these sensors can trigger an immediate stop or prevent the start of the palletiser.

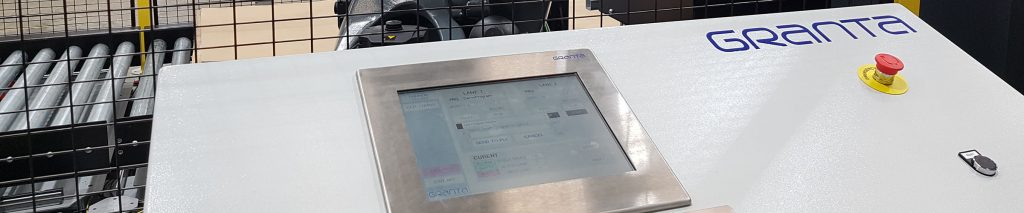

- Safety Controller: Modern palletisers often use safety programmable logic controllers (PLCs) or safety relays that are designed to monitor and control safety-related functions. These safety controllers are used to manage the door interlock switches, light curtains, area scanners, and other safety devices to ensure that the palletiser remains inactive when someone is inside the cell.

- Emergency Stop Buttons: Emergency stop buttons are strategically located around the palletiser cell. If someone needs to stop the palletiser quickly for safety reasons, they can press an emergency stop button to halt all machine functions.

- Safety Reset Button: If the safety system is triggered it has to be reset manually by someone with a clear view of the cell. The palletiser system reset button will not activate the palletiser without the above safety systems being in place. This means that the system will not start without an operator manually confirming the cell is empty and safe to run, this provides a further layer of safety protection.

All safety devices are dual channel ensuring that if one channel is broken the other channel will still be active. If any point in the safety system is compromised (e.g. a wire to a light curtain is cut) the safety system will stop the palletiser from running.

It’s important to note that the specific safety features and systems employed can vary depending on the type and design of the palletiser, as well as local safety regulations and industry standards. Regular maintenance and testing of these safety mechanisms are critical to ensure their reliability and effectiveness in preventing accidents and injuries. Always follow proper safety protocols and guidelines when working with industrial machinery.

If you would like to know more about palletisers and their safety systems, feel free to contact us on 01223 499488 or helpline@granta-automation.co.uk.

Find out more…

- What Stops A Palletiser From Starting If Someone Is In The Cell?

- Can A Palletiser Be Purchased as OpEx rather than CapEx?

- How Often Do Palletisers Break Down?

- How Easy Is ‘Easy Programming’ Palletiser Software? How Does It Differ To Traditional Palletisers?

- Robotic Palletiser vs Layer Former Palletiser

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 81

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 86